Drilling |Tunneling And Tunneling Methods In Civil Engineering

Drilling & Tunneling In Civil Engineering |8 Tunneling Methods That Every Civil Engineer Knows

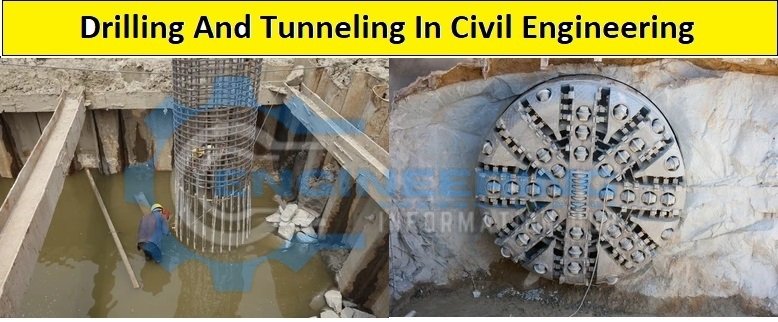

Drilling And Tunneling In Civil Engineering

Civil engineering nowadays plays an essential role in building our infrastructure and the environment. Drilling and tunneling techniques are critical to this type of engineering. Several construction projects, transportation systems, underground utilities, and resource extraction require these techniques. Drilling & Tunneling In Civil Engineering |8 Tunneling Methods That Every Civil Engineer Knows |Drilling |Tunneling And Tunneling Methods In Civil Engineering

Let’s explore the significance of drilling and tunneling in civil engineering and how they contribute to the development of modern society. We will discuss various tunneling and drilling methods in detail, so let’s get started.

8 Tunneling Methods That Every Civil Engineer Knows

Since the 1950s, trenchless drilling and tunneling have transformed how utilities and piping are laid and maintained underground. Over the past few decades, many different types of tunneling methods have been developed as technology has advanced. Various methods have advantages and disadvantages and are better suited to specific applications. A civil engineer knows better which method to use in which situation.

Horizontal Auger Boring

Horizontal auger boring machines resemble giant screws, which spin as they travel down into the soil. The spiral edges of the auger bring displaced soil out of the rear of the machine. There are usually several stages involved in auger boring:

- A segment of piping penetrates the soil.

- Within the new pipe segment, soil is removed using an auger bore.

- The auger machine digs soil out of the tunnel as it advances.

- As soon as the next segment is completed, the process begins again.

An auger drilled horizontally is ideal for laying pipes in soft soil in straight horizontal lines.

-

How To Calculate The Estimate of Building Construction

-

Calculate The Number of Items for The Stair Case

-

Types of Loads How To Design Wind Load |Purpose of Load Calculation

Method of Drilling and Blasting

The method involves drilling holes in rocks and loading explosives into them. The explosion is triggered by activating the detonator attached to the explosives and the rock particles that were transported from the tunnel. Controlled blasting should be conducted to avoid faults occurring in adjacent rock masses. Otherwise, the tunnel’s stability will be compromised.

Ramming Pneumatic Pipes

Pipe ramming, or pneumatic pipe driving, involves piping or pipe casings into the ground using compressed air. The process involves repeatedly striking the rear of the pipe with a rammer. Pipe casings with sharp edges are fitted with soil-cutting shoes that penetrate the soil. The pipe casings may be slipped behind the cutting edge using a lubricant like bentonite to facilitate cutting.

Adapters protect pipe casings at the rear end, which are exposed when rammer blows are applied. There are several methods of removing soil, depending on the size of the pipe bore: auger boring, water jetting, or compressed air. Pipe ramming using pneumatic devices is a suitable method of laying pipes directly in a straight line in shallow ground. To free up a stuck pipe, use the ramming process with another tunneling technique.

Guided Boring

Using guided boring, an accurate path can be controlled for a pipe to travel through the ground. A laser guiding system provides precise guidance for the drill along a precise path as close to one inch as possible. A guided boring operation consists of two steps. The first step involves drilling a trial tunnel along the required route. Drill heads with curved or slanted heads or fluid jets can be adjusted to control the direction of the drill.

A back reamer increases the hole’s diameter after completing the pilot bore. Due to their complexity, a guided boring operation requires skilled personnel and expensive laser guiding equipment. The guided boring method, however, is more advantageous when accuracy along a desired path is of the utmost importance.

Cut and Cover Method

Tunnels that are shallow or small are constructed using the cut-and-cover method. It involves excavating a trench, building the tunnel (base, side, and roof walls are constructed), and covering it. Compared to other tunneling techniques, it is the oldest and most economical method. This method also utilizes precast materials. Underpasses and small underground passageways are constructed using this method in urban areas.

Hammer Down the Hole

In trenchless tunneling, down-the-hole hammers are used to deal with hard rock. Machines that drill horizontally may encounter rock that the machine cannot penetrate. A down-the-hole hammer is used rather than excessive force and wears to prevent damage to drilling heads.

Construction workers have a similar piece of construction equipment that they use to break through the concrete and asphalt surfaces of roads. A pneumatic hammer delivers blows that drive the hammer into the rock. In addition to the rotational force of the drill, it takes advantage of the attaching mechanism on the drill string.

Dust and rock chips are removed from the cutting surface by the use of compressed air. Among other tunneling methods, down-the-hole hammers are used to facilitate the removal of hard rock that does not allow the job to be completed.

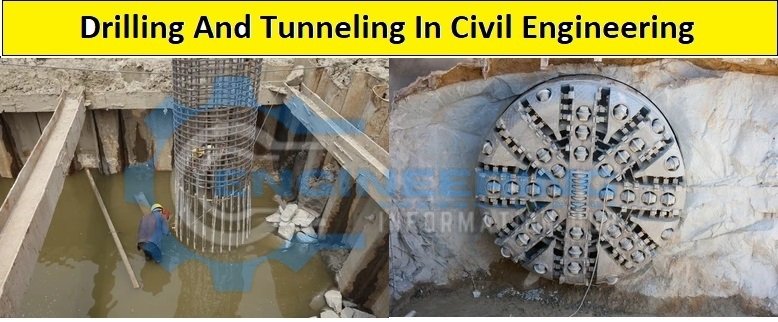

Pipe Jacking/Tunnel Boring

Boring tunnels and installing piping segments require hydraulic jacks, whereas tunnel boring machines remove soil from an entrance pit. Tunnel boring machines have various cutters for excavating soil while drilling the pipe.

This technique is useful for laying pipes directly through rocky and complex soil conditions and can be applied to any type of ground condition. The tunnel boring/pipe jacking method is suitable for laying long pipe lengths and pipes with large diameters.

Surface Casing

A range of trenchless methods are available for surface and pipe casings. The purpose of this technique is to install a continuous casing using the tunneling process. The product pipe is inserted into the casing once the casing is in position.

A surface casing installation can be costly due in part to materials. However, the resulting installation provides excellent protection against corrosion. This protects the pipes from the stresses associated with tunneling itself, as well as from any additional excavations that might damage them.

Conclusion

Drilling and tunneling form the backbone of infrastructure development and resource extraction. These fields are crucial for creating stable foundations, constructing tunnels, installing underground utilities, and extracting valuable resources from the earth.

With advanced technologies and innovative techniques, civil engineers continue to shape the modern world, ensuring safe and efficient transportation systems, sustainable construction practices, and environmental stewardship.

Related Post

-

How To Make Method Statement For Excavation And Backfilling

-

Basic Purpose To Use Spread Foundation/Footings

-

How To Repair The RCC Structures And How To Repair Leaks Roof

-

Load Calculation For Column Beam And Slab Design Calculation

-

Why Using The Crank Bar In Slab Column RCC Beam