What are The causes of building cracks

What are the causes of building cracks?

In This Article, I will discuss What are The Causes of building cracks introduced Of Cracking and the Causes of Cracks, The Size of cracks | Shapes of cracks.

What are The Causes of building cracks

Introduction of cracking

Structures and alternative erected structures are moving all the time, however, typically these movements are thus tiny on be obscure. The movement will be caused by blights, movement of the bottom, foundation failure, decay of the structure cloth, and so on.

Still, cracking is probably going to try and do, if a structure is unfit to accommodate this movement. the looks of deformations and cracks will be visually monstrous and distressing for inhabitants, and if left undressed they will have an effect on the integrity, safety, and stability of the structure.

Effective treatment needs initial that the causes of cracking are understood. Solely can also a method for type be implemented?

Causes of Cracks

The basic common causes of cracking are

Ground movement (beneath foundations) is caused by complexion loss, landslip, vibration, subsidence, agreement, heave, sway, and so on.

Foundation failure thanks to the decay of soppy complexion slipup, Concrete corrosion thanks to chemical pollutants so on.

Decay of the structure cloth, thanks to the worm, rust, and so on.

Humidity movement that causes accouterments to expand or contract is also thanks to the presence of foliage or defective or broken rainspouts.

A thermal movement that causes accouterments to expand or contract as the temperature will increase or diminishments.

Essential blights, notably in major structures.

Faulty or broken rainspouts.

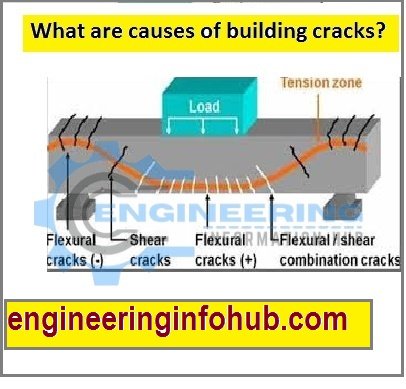

Suspended structures similar to bottoms that distort underneath merchandise.

Tree root growth.

Absence of foundations in aged structures

Size of Cracks

BRE assessed a variety of parcels as a part of a study that was printed as BRE Digest 251 Assessment of injury in low-rise structures.

This joined six orders of cracks alongside the everyday harm caused and therefore the remedy required

1-Hairline cracks Lower than0.1 millimeters in vary. No type of action is required.

2-Fine cracks Up to one millimeter in varying typically confined to internal wall home stretches fluently treated victimization traditional decoration

3- Cracks fluently crammed Up to five millimeters in vary. Not ineluctably visible outwardly, however doors and windows could bear conformist to assist projected. will be cloaked by appropriate stuffing

4- Cracks that bear gaps up to Extents of 5-15 millimeters. Weather- minginess, and repair pipes are also affected. External masonry may have repointing or, in some cases, to get replaced.

5- Expansive harm Extents of 15-25 millimeters. Windows and door frames come back distorted, walls spare or bulge perceptibly. needs breaking-out and relief of wall sections

6- Structural harm Extents lesser than twenty-five millimeters. Shafts lose their bearing, walls bear shoring, and therefore the structure is usually unstable. could bear major type workshop

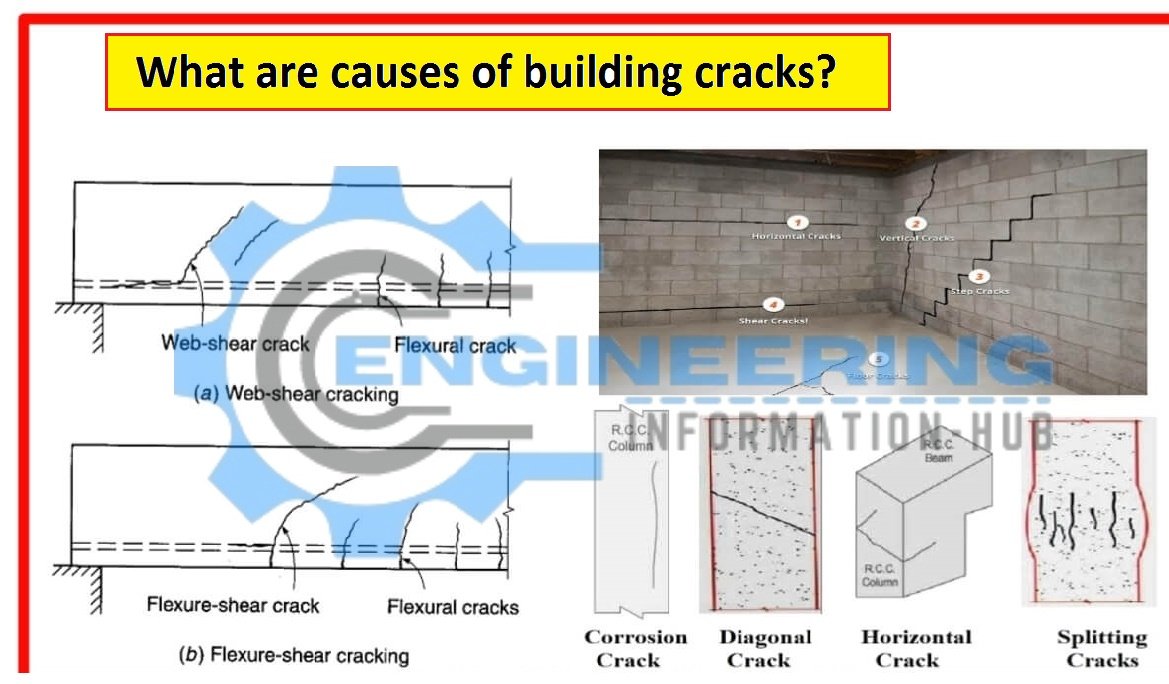

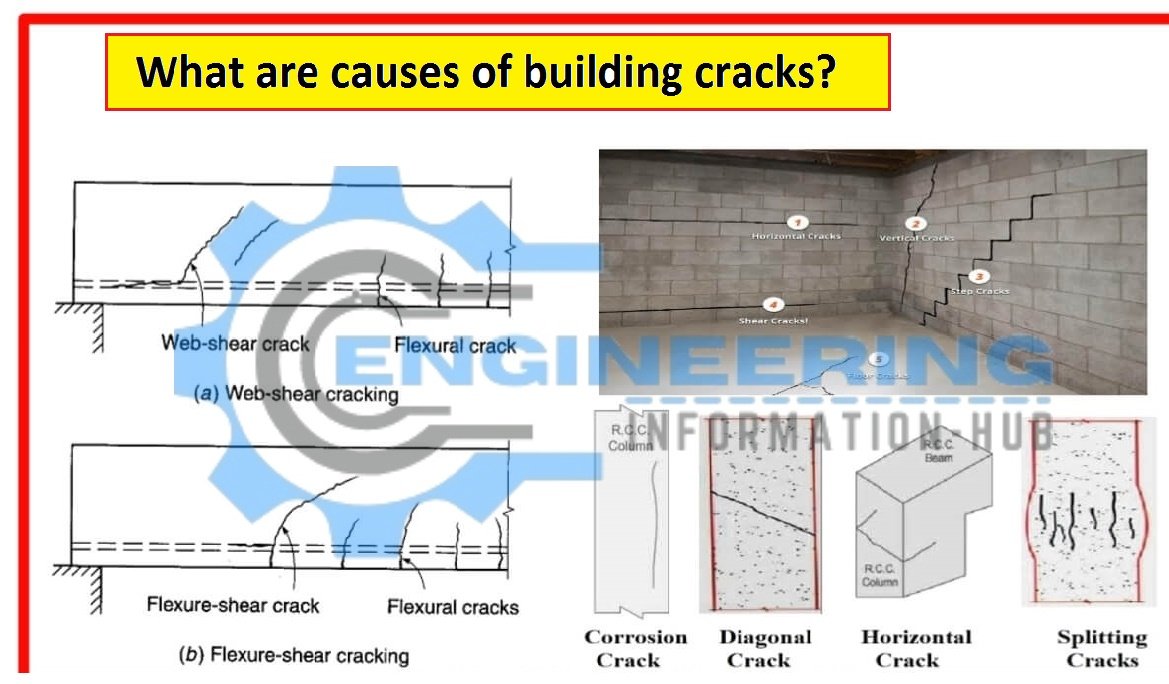

Shapes of Cracks

Hairline cracks are common in various structures, notably in poultice, which is at risk of shrinking and is veritably sensitive to movement.

Stepped cracks tend to follow the lines of vertical and perpendicular joints in structures, similar to beds of mortar between bricks or blocks, and will indicate structural movement.

Vertical cracks could indicate that structural factors similar to bricks or blocks have been unsuccessful so will be an indication of great stresses among the structures

Cracks that are wider at the highest or at the very cheap could indicate that there has been foundation movement, with the direction of the widening giving a suggestion of the seeming direction of the movement.

Vertical cracks could indicate that a component similar to a wall is failing and this might gift a security concern.

Learn more

How To Estimate The Materials For Concrete Work

Coping with cracks

Contrivers of recent structures could strive to‘ style out’ various of the causes that will cause cracking by the careful style of the foundations and structure, introducing movement joints, specifying accouterments that may tolerate movement, and so on.

Being structures ought to be examined for the seeming explanation for movement, Associate in Nursing whether or not this is often thanks to an external issue (similar to subsidence), or is caused by the material of the structure itself (similar to a poor grade of cement). it is important to ascertain whether or not the cracking is probably going to be progressive and deteriorate additional, and if so, to what extent and over what amount of your time. Exploration of repository data, similar to former checks, will facilitate this assessment.

Form methods will vary from major interventions to restricted decorative workshops. Still, unless the underpinning cause has been prohibited, it’s seemingly that further conservation work is going to be required in the future. The movement caused for illustration by vibration or by thermal enlargement and compression is probably going to persist. During this case, type accouterments should be chosen precisely; those with the aptitude to distort in a very plastic manner are going to be additional palm than people who merely increase strain around the crack so are seeming to sire the shape to fail.

For illustration, hydraulic or fat limes could provide enough physical property to accommodate strain. Erosion-resistant pristine blade mounts will be fitted into bed joints to cut back the threat of failure by redistributing strain and stress over a wider space.

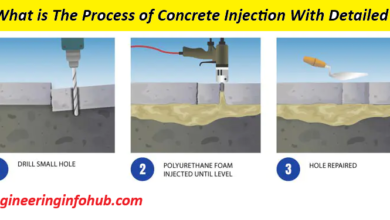

Instruments similar to boors copes will be wont to notice voids that will have opened as a result of movement. Grouting voids to fill them with cementations material will provide a result if the underpinning cause has been prohibited.

Where underpinning of foundations is required, a variety of indispensable ways is out there. See bolstering for additional data.

Rather than merely covering up issues, it is important to grasp the rationale that cracks have passed, notably if they are massive, or if they are adding in size, and it’s going to be knowing obtain a professional recommendation.

Learn More

Bar Bending Schedule For The Staircase

Basic Information For Civil Engineering

Thanks for Reading Article Get more Information and share it with others.

JOIN US & LIKE MY OFFICIAL FACEBOOK PAGE

THANKS

One Comment