Introduction And Calculation Of Elevation With Rise Fall Method With Step

Introduction Of Rise Fall |Calculation Of Elevation With Rise Fall Method |Step Calculation Of Elevation With Rise Fall Method

Introduction And Calculation Of Elevation With Rise Fall Method With Step

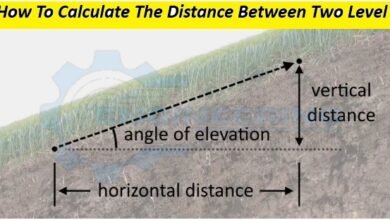

This article is related to finding the calculation of elevation and the introduction and steps of the Rise Fall method. In this method the calculation of land with the help of the rise-fall method. in this method, we calculate the elevation difference between two leveling points during leveling work. must be known about some trick in the calculation.Introduction And Calculation Of Elevation With Rise Fall Method With Step.Introduction Of Rise Fall |Calculation Of Elevation With Rise Fall Method |Step Calculation Of Elevation With Rise Fall Method

Ist Reading OR Backsight

After setup leveling machine on the given benchmark then taken Ist reading which is called back sight or Ist Reading. this reading is taken on the benchmark.it is also called B.S

Inter Sight OR Intermediate Sight

When taken back sight then after taking all reading before Foresight that is called inter sight.it is also called I.S.

Foresight OR last Reading

This reading is taken when we need to shift the equipment mean level machine. that is called Fore Sight is also called F.S.

Other Post

-

Calculate The Back Sight with one Control point and Angle

-

Layout of Structures in Civil Engineering

-

How to Calculate Distance and Bearing between Coordinates

-

Resection Method in Civil & Land Surveying

Given level OR Benchmark

This is given level or elevation that is called Bench Mark.it is also called B.M

Rise Wall Calculation Step

Calculate the Rise Fall Formula

1-Back Sight – Inter Sight OR Inter sight – Foresight

B.S – I.S OR I.S – F.S

WHEN

2-Back sight – Fore Sight = +ve means Rise

Backsight – Fore Sight = -ve means Fall

3-Find The R.L

New Reduced level

New Reduced level = GIVEN R.L – Fall = GIVEN R.L +RISE

Cross Checking of Arithmetic Calculation

∑Backsight -∑ Foresight = ∑Rise -∑Fall = Last Reduced Level – Ist Reduced level

∑ = means the sum of all

There are all steps to find the Rise and Fall method Calculation.

Example With All Calculation.

Read More

-

What Is The Surveying And Types Of Surveying With Detail

-

Surveying And Principle Of Surveying In Civil Engineering

-

Difference between Whole Circle and Reduced Bearing

-

What Is The Traverse Types Of Traverse And Method Of Traversing

-

What Is The Cut Fill And Method to Calculate The Cut And Fill

-

What Is The Bone/Breast Wall |Uses |Advantages And Disadvantages

Thanks For Reading the Article Get More Information And Share it With Others

JOIN US & LIKE MY OFFICIAL FACEBOOK PAGE

2 Comments