Calculate The Back Sight with one Control point and Angle

Calculate The Back Sight with one Control point and Angle |How To Take The Backlight on Total Station With One Point

Calculate The Back Sight with one Control point and Angle

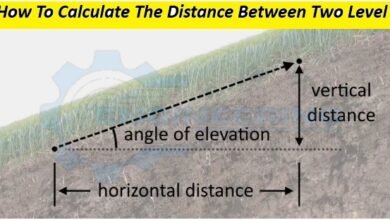

Today I have a topic about land surveying. I explain how we set the total station when I have only one point. how to take the backlight on total station with one point and how to shift the mora points with help of one point this topic is very important for the land surveyor and very helpful for that surveyor which is working in that site which have just a one branch mark or temporary point.Calculate the Back Sight with one Control point and Angle

Calculate the Back Sight with one Control point and Angle

what is the total station?

The total station is the instrument of land surveyor which is used for marking any projects. marking means layout or showing any points from drawing to site. and use these instruments for more purposes as to find the angle centerline, direction, height and etc.

Now I explain Back Sight with one Control point and Angle

Learn more

Stairs Types of Stairs and Principles of Designing of Stairs

Layout of Structures in Civil Engineering

In ist point must know what is the setting of the total station.

The setting of the total station means centering leveling and focusing.

Centering

centering means setting the total station on the try pod stand and the lock base plate with a screw attached try pod stand and then checking the center point with the help of a centering eye lens and setting the machine on the exact point on the center.

Leveling

Leveling means the total station doing the level with the help of bubble level which has in total station base plate or tries birch plate. and with the help of leveling screw and try pod legs do the leveling.

Focusing

Focusing means the focus of the telescope of the total station with the help of focusing screw and targeting the object.

I set the total station on that points which are given by Northing and Easting. Suppose we have Northing And Easting is 1000 and 500. I set the total station on this point.

Know we take the backlight with one coordinate

our all setting of the total station is complete and I already set the total station on one point. now how to take backsight.

How?

when you are working on any site or project you must know about the time of sunrise in that city or location. you will find it easy with the help of any Islamic calendar or the help of google. because I find the 2nd coordinate with the help of the sun.

Note

when the sunrise starts time and up to 8 mint the sun is exactly 90 degrees. after 8 mint the sun changes the degree. some locations this time is 7 mint and some locations this time is up to 9 mint so that is why we take 8 mint or less than 8 mint. so before the sunrise starting time we all complete set of the total station on one point which is given. then we set the backsight in the direction of the sun approximately the centerline of the sun and with the backlight in angle or bearing.

This is the one way when we are working in the day time, but if we working in night time then how to set the total station with one point.

When we working night time then the same all step up to a setting of the total station. night time on the sky one stars which have light is two much high with comparing the others stars. This is the mane star that the name of the polar star. this star is 0 degrees.

so we take backsight on this star and put the angle or bearing is 0 degrees.

This all topic is practical and very important for a land surveyor

Others post

Why Using The Crank Bar in Slab Column RCC

Layout of Structures In Civil Engineering

Thanks for Reading Article Get More Information And Share it With Others

2 Comments