What is the Septic Tank | Tank Working of a Storage Tank

What is the Septic Tank | Tank Working of a Storage Tank | Underground Septic Tank | Septic Tank Maintenance

What is the Septic Tank | Tank Working of a Storage Tank

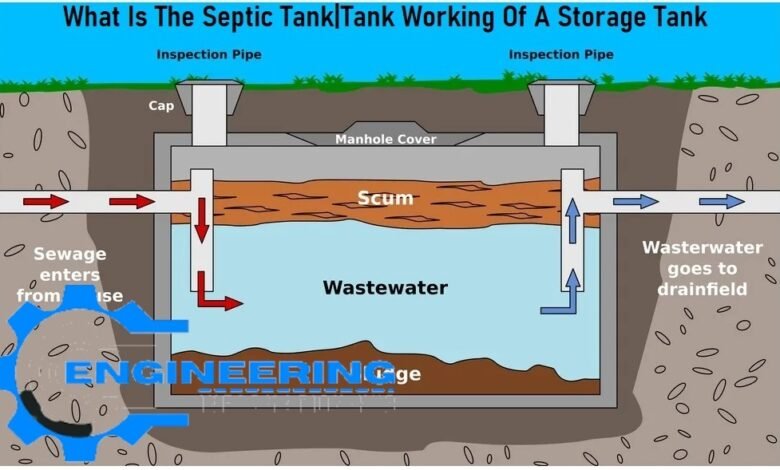

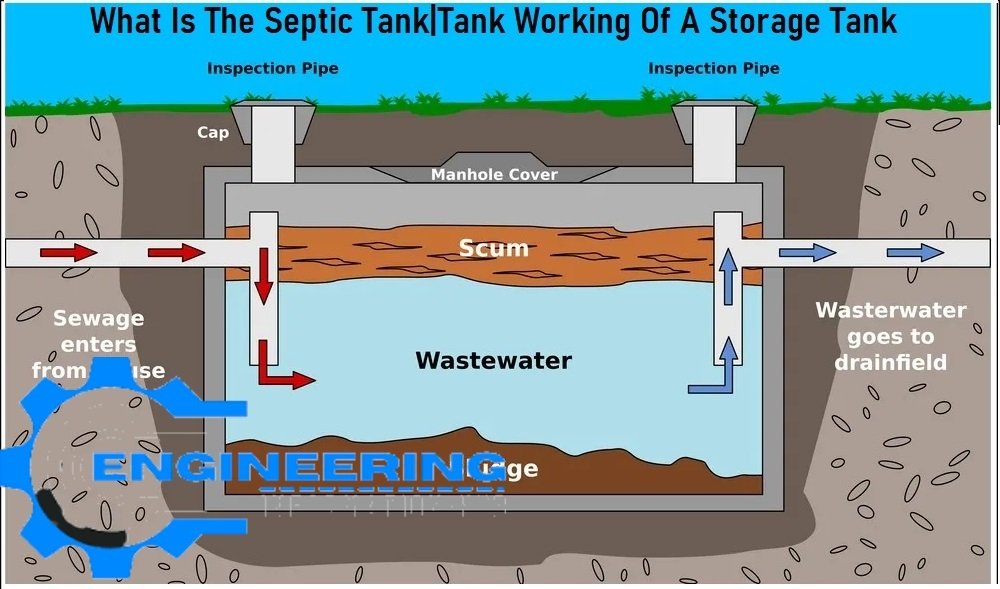

.Today, I have the topic of septic tank defination of septic tank. estimate of the septic tank.What Is The Septic Tank|Tank Working Of A Storage Tank.What Is The Septic Tank|Tank Working Of A Storage Tank|Underground Septic Tank| Septic Tank Maintenance

What is The Septic Tank

A storage tank is associate underground geological phenomenon tank in an exceedingly sewer water treatment system. they’re manufactured from covering material, plastic, or concrete and might have one or additional tanks. One finish of the storage tank is connected to a sewer water recess pipe and also the alternative finish to a septic drain field.

The term “septic” indicates to anaerobic microorganism atmosphere developed within the tank to decompose the waste discharge within the tank. the look of the storage tank incorporates 2 chambers with associate access gap and canopy. A dividing wall having openings set regarding midway between the ground and roof of the tank separates them.

Natural proved technology and processes ar employed in a storage tank to treat sewer water from house plumbing made by loos, room drains, and laundry. Septic tanks ar sometimes rectangular or spherical in form. The T-shaped outlet and compartments of the tank forestall the sludge and scum from going away the tank and traveling into the drain field space. Septic tanks ar continuously put in underground and frequently fifty meters aloof from the house and regular maintenance is obligatory.

Working of A Storage Tank

All septic tanks ar connected with 2 pipes; recess and outlet. The water waste from the home is transported by the recess piping and it’s then collected within the storage tank. within the tank, the sewer water is keep for an extended amount of your time so the storage tank digests/decomposes the organic matter and separates floatable and solid matters like grease/oil from the sewer water.

The outlet pipe is additionally referred to as the drain field pipe that moves the processed sewer water from the storage tank to unfold it within the soil and watercourses. The sewer water within the storage tank is separated into three layers

The top layer consists of oils and grease. It floats specifically the waste and is sometimes referred to as “scum”.

The middle layer contains the sewer water along side waste particles.

The third and bottom layer consists of serious particles that type a layer of sludge.

The bacterium gift within the storage tank break down the solid waste of the sewer water that is then separated and drained simply. the left-over within the tank ought to be sporadically removed throughout maintenance.

Underground Septic Tank

The following is that the basic stepwise method by that a storage tank usually works.

Domestic water from the toilet and room runs through one main emptying pipe resulting in the underground storage tank.

The sewer water is command within the storage tank for a few time wherever the separation and decomposition method starts.

The liquid effluent exits to the tank into the drain point.

This pretreated sewer water is then discharged through pipes onto porous surfaces that filter through the soil.

Finally, the sewer water naturally removes the harmful bacterium, viruses, and nutrients because it percolates into the soil.

EN12566 provides the overall needs for domestic water treatment facilities.

Septic Tank Maintenance

The maintenance of the septic system should be sporadically wiped out order to attain correct operating of the system. In general, it’s the responsibility of the owner. Regular storage tank maintenance helps in

Clearing the recess drain blocks generated thanks to excessive disposal of preparation oils and grease.

Cleaning the clogs with non-biodegradable waste things down the rest room like smoke butts, and cotton buds/swabs.

Remove the food wastes that quickly overload the storage tank system.

Eliminating sure chemicals like pesticides, herbicides, bleach, hydrated oxide, etc which can harm the storage tank or kill the bacterium.

Cleaning the biofilms developed on the pipe will result in blockage.

Some makers promote the utilization of sure storage tank additives to enhance the effluent quality from the storage tank. There may be some environmental issues thanks to storage tank operation like:

Odor And Gas Emissions

Septic tank failures will produce pathogens which will produce dangerous diseases.

In extremely dense areas groundwater and surface pollution could occur

Types of storage tank Systems

Septic systems vary wide in their style and sizes. numerous factors ar chargeable for these changes. a number of the vital factors are:

household size,

soil type,

weather conditions,

site slope,

lot size,

proximity to sensitive water bodies,

even native laws

Some of the foremost common sorts of septic tanks are:

Conventional septic system consisting of a storage tank and a trench or bed underwater sewer water infiltration system.

Chamber septic system together with open-bottom chambers, fabric-wrapped pipe, and artificial materials.

Drip distribution septic system with an outsized dose tank when the storage tank.

Aerobic treatment unit.

Mound septic system

Recirculating sand filter septic system

Evapotranspiration bed septic system

Constructed soil septic system

Cluster septic system.

Read More

-

Transportation Concrete Importance Type And Method Of Transportation Concrete

-

How To calculate the estimate of Septic tank

-

Calculate The Estimate Of The Soakage Pit

-

Calculate The Rectangular Water Tank Size And The Capacity

-

Calculate The Formwork For Columns Beam Girder And Slab

-

How To Calculate The Estimate Of Building Construction

-

Bar Bending Schedule For The Staircase

One Comment