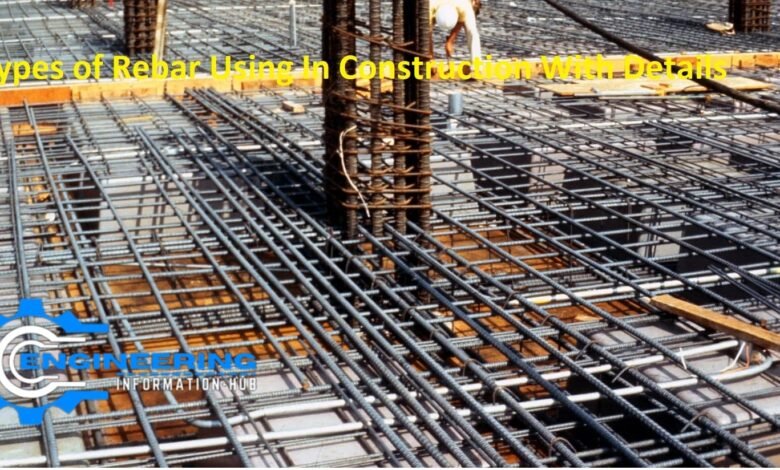

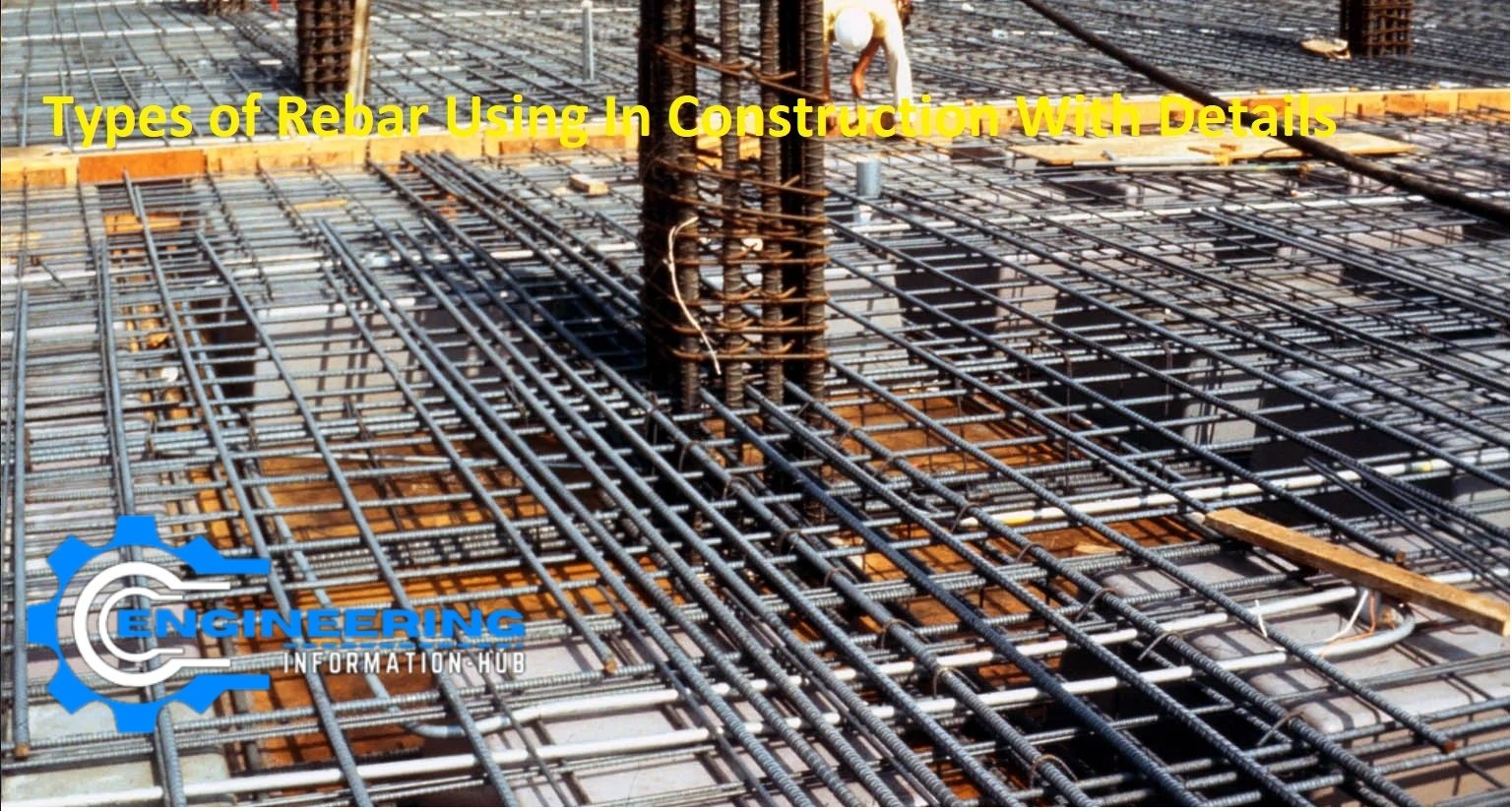

Types of Rebar Using In Construction With Details

Types of Rebar |Rebar Using In Construction |Types of Rebar Using In Construction With Details |Carbon Steel Rebar |Rebar Using In Construction |Stainless Steel Rebar |Galvanized Rebar Glass Fiber Reinforced Polymer( GFRP) Rebar |Epoxy-Coated Rebar |Welded Wire Fabric( WWF) Rebar |Expanded Essence Rebar

Types of Rebar Using In Construction With Details

Choosing the suitable rebar for your design will depend on the size and grade demanded to add the necessary support and strength. Carbon sword rebar is the standard in concrete and construction assiduity, but it may not hold up well in high-humidity surroundings. Types of Rebar |Rebar Using In Construction |Types of Rebar Using In Construction With Details |Carbon Steel Rebar |Rebar Using In Construction |Stainless Steel Rebar |Galvanized Rebar Glass Fiber Reinforced Polymer( GFRP) Rebar |Epoxy-Coated Rebar |Welded Wire Fabric( WWF) Rebar |Expanded Essence Rebar

Rebar Using In Construction

Choosing the suitable rebar for your design will depend on the size and grade demanded to add the necessary support and strength. It’ll also largely depend on the material used to make the rebar, as well as what’s used to cover it.

Carbon sword rebar is the standard in concrete and construction assiduity, but it may not hold up well in high-humidity surroundings. An epoxy resin-carpeted rebar may work more in maritime operations, retaining the strength and continuity of the concrete without accelerated erosion.

Types of Rebar Using In Construction

-

Carbon Steel Rebar

-

Stainless Steel Rebar

-

Galvanized Rebar

-

Galvanized Rebar

-

Glass Fiber Reinforced Polymer( GFRP) Rebar

-

Epoxy-Coated Rebar

-

Welded Wire Fabric( WWF) Rebar

-

Expanded Essence Rebar

Carbon Steel Rebar

Carbon sword rebar is the most common type of rebar used in domestic and marketable systems. This amalgamation sword is exceptionally cost-effective and durable, but the carbon sword may not hold up well to systems with high humidity exposure. Using carbon sword rebar may be parlous if you work with high humidity content or in high-moisture areas.

Stainless Steel Rebar

Although not as cheap as carbon sword rebar, pristine sword rebar can be a feasible volition. These sword buttressing bars are used for islands, roads, piers, and other weight-supporting structures. Unlike carbon sword rebar, pristine sword rebar can help with erosion, giving you added protection.

Galvanized Rebar

One of the more precious options, galvanized rebar, is an amalgamation of sword rebar dipped in a zinc result to add a special water coating that can discourage erosion. This material is an excellent volition to epoxy resin-carpeted rebar. Galvanized rebar is 40 times more resistant to erosion and holds over more during shipping and installation.

Glass Fiber Reinforced Polymer( GFRP) Rebar

Also known as fiberglass rebar, this material is perfect for systems that are exposed to water. Glass fiber rebar will noway erode and boasts a much lesser tensile strength than traditional sword rebar. Plus, it’s 75 lighter than the sword, which means you can save on expensive shipping charges. This technical material also has non-conductive electrical parcels.

Epoxy-Coated Rebar

Epoxy-carpeted rebar works well in high-moisture and high-humidity construction systems. The rebar is carpeted with a thick epoxy resin, which helps to decelerate erosion. Unfortunately, the delicate epoxy resin coating can come scratched and damaged during shipping, rendering the rebar much less effective against erosion.

Welded Wire Fabric( WWF) Rebar

Although this type of material has a different kind of name than other standard rebar types, WWF rebar is actually a grid pattern made of welded low-carbon sword line. The grid can help support concrete crossbeams to ameliorate the overall tensile strength of the concrete.

Expanded Essence Rebar

Analogous to WWF rebar, expanded essence creates an essence mesh that’s detailed in diamond- shaped lines. The mesh is made from a single sword distance that’s consummately cut and expanded. This material is generally used when extremely thick cataplasm is demanded to support the concrete. Expanded essence rebar is frequently used for sidewalks or walking shells, but it isn’t strong enough to repel heavy vehicle business or heavy weights.

Conclusion

Rebar is an essential material for corroborated concrete. Choosing the proper size, grade, and type of underpinning bars is pivotal to the success of any design. Proper and indeed distance is also important. Completely understanding each rebar grade’s tensile and yield strength, as well as the benefits, disadvantages, and overall cost difference between your rebar options will allow you to produce a safe, cost-effective, and durable design.