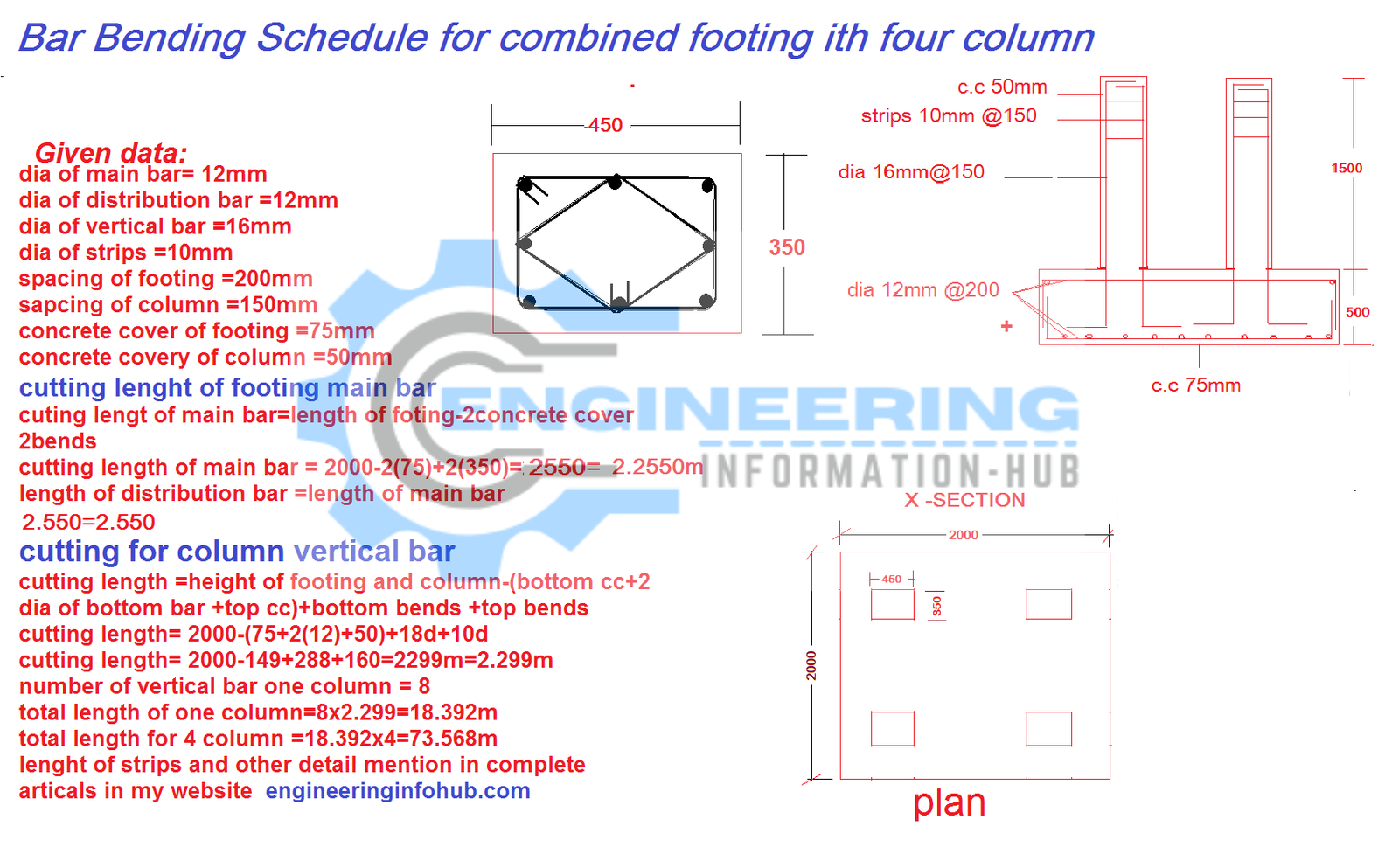

Bar Bending Schedule For Combined Footing With Four Column

Bar Bending Schedule For Combined Footing With Four Column

What is the combined footing?

when we make the combined footing then the soil capacity is a low and small distance between two-column.

In this article, we will calculate the bar bending schedule for that footing has four-column and we will find the complete detail of the rebar step by step.

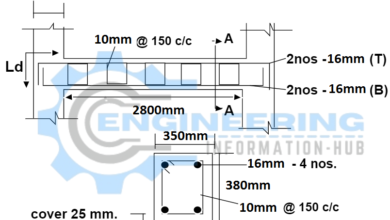

we have some given data

dia of footing main bar =12mm

dia of footing distribution bar =12mm

spacing of footing=200mm

concrete cover of footing=75mm

dia of vertical bar in column=16mm

dia of strips =10mm

spacing of column=150mm

concrete cover of column=50mm

Now we calculate the cutting length of the main bar

LEARN MORE

Bar Bending Schedule of Circular Column

cutting length of main bar=total length of footing-2c.c+2bends

cutting length of main bar=2000-2(75)+2(350)

cutting length of main bar=2000-150+700=2450=2.550m

Nos of main bar=total length/spacing+1

Nos of main bar=2000/200+1=11nos

total length of the main bar =length of one bar × nos of main bar

total length of the main bar =2.550×11=28.05m

weight of main bar= d²/162.25×total length

weight of main bar=12²/162.25×28.05=24.89kg=25kg

length of distribution bar=length of the main bar

28.05=28.05m

the total length of the main bar and distribution bat=56.10m

wight also same

25kg=25kg

total weight of 12mm bar for footing =50kg

the vertical bar of column

cutting length of vertical bar=total height of footing and column-bottom c.c -2dia of the bottom bar -top c.c +bottom bends+top bends

cutting length of vertical bar=2000-75-2(12)-50+288+160

cutting length of vertical bar=2000-149+448=2299=2.299m

nos of bar=8

total length of vertical bar =length of one bar ×nos of bar

the total length of vertical bar = 2.299×8=18.392m

weight of vertical bar=d²/162.25×total length

weight of vertical bar=16²/162.25×18.392=29.01kg=29kg

we have four column

Other post

How to Calculate the Concrete of Volume for the Staircase

so

length of one column ×4=18.392×4=73.568m

weight of one column×4=29×4=56kg

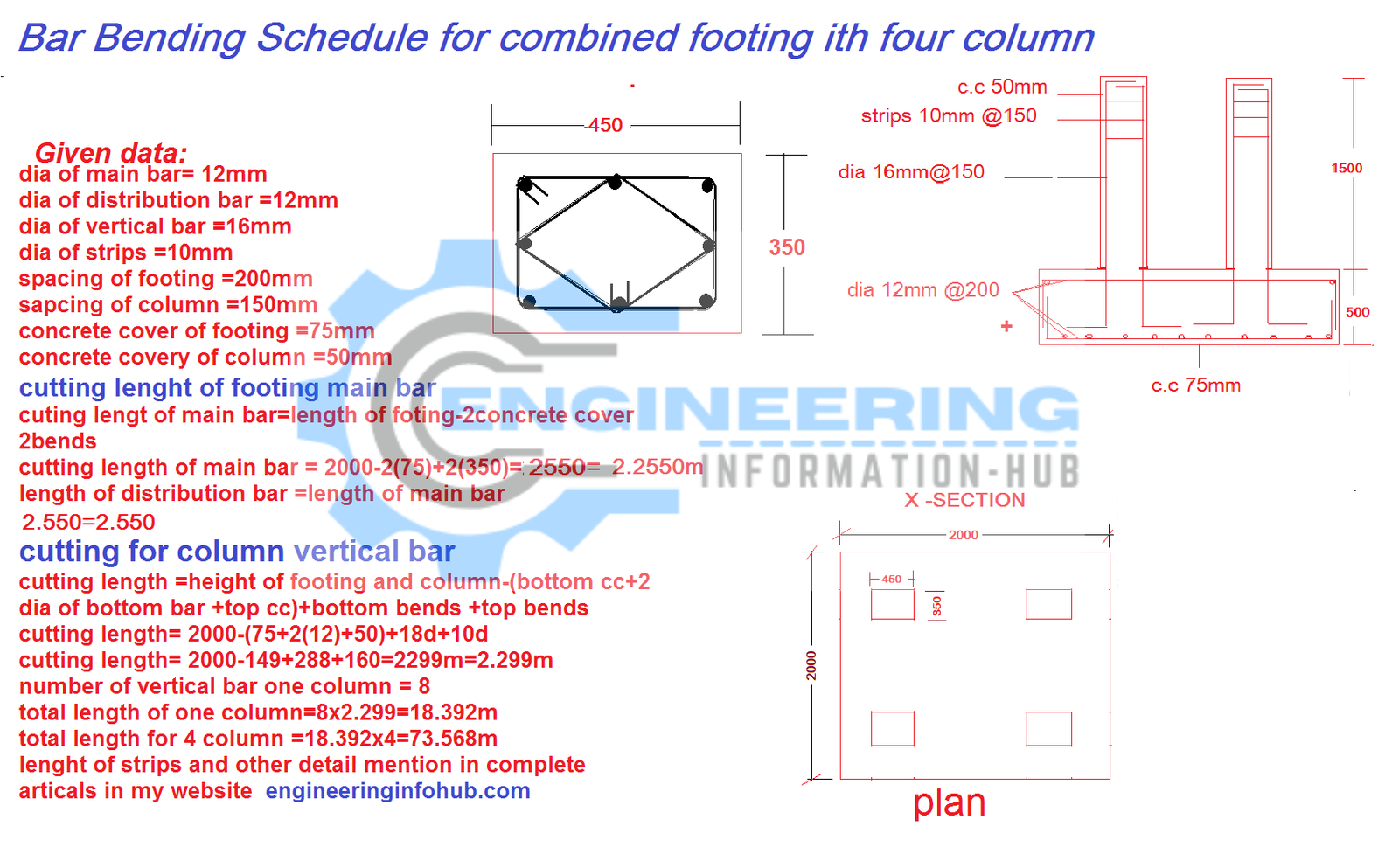

Stips of column

nos of strips(Rectangle) =total height of column/spacing+1

nos of strips (rectangle)= 1500+150+1=11nos

cutting length of strips (Rectangle)=2side of 350+2side of 250+2bends (9d)

cutting length of strips (Rectangle)= 700+500+2(90)=1.380m

total length of strips=length of one stips×nos of strips

total length of strips=1.380×11=15.18m

weight of strips (Rectangle)=d²/162.25×total length

weight of strips (Rectangle)=10²/162.25×15.18=9.356kg=10kg

we have four column

so

length of one column ×4=60.72m

weight of one column×4=40kg

Now calculate the diagonal stips

length of strips =4sides of in diagonal +2bends(9d))

length of strips =4×215+2(9×10)=860+180=1040=1.040m

nos of strips =total height/spacing+1=1500/150+1=11nos

total length of strips=length of one strips ×nos of strips

total length of strips=1.040×11=11.44m

weight of stips =d²/162.25×total length=10²/162.25×11.44=7.05kg= 7kg

we have four column

length of one column stips×4=11.44×4=45.76m

weight of one column strips ×4=7×4=28kg

Now

total length of 12mm bar =56.10m

total weight of 12mm bar =50kg

total length of 16mm bar=73.56m

total weight of 16mm bar =56kg

total length of 10mm bar =68kg

total weight of 10mm bar =110kg

Good information

I have become a fan of your blog. Hope for our further opportunities to acknowledge and build up our engineering, technical knowledge.