How To Calculate The Distance Between Two Level

Calculate The Distance Between Two Level |How Slope Works In Paving Concrete

How To Calculate The Distance Between Two Level

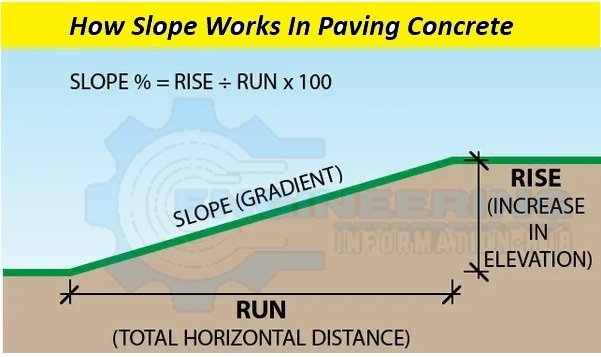

The slope in surveying, refers to the steepness or incline of a surface, typically the ground. It is often expressed as a ratio of vertical rise to horizontal distance, or as an angle of inclination relative to the horizontal plane. How To Calculate The Distance Between Two Level

The slope is an important measurement in various fields such as civil engineering, construction, and land development, as it determines drainage patterns, stability of structures, and suitability for use.

In paving concrete, the slope refers to the intentional incline or gradient designed into a paved surface.

How slope works in paving concrete

- Surface Drainage: Slope is crucial for ensuring proper drainage of water away from the paved area. Without an adequate slope, water can pool on the surface, leading to potential damage and safety hazards.

- Design Considerations: Engineers and designers calculate the required slope based on factors such as expected rainfall, surface area, and drainage requirements. Typically, a minimum slope of 1-2% (1/8 to 1/4 inch per foot) is recommended for most paved surfaces to facilitate drainage.

- Construction: During the construction phase, surveyors and engineers use instruments such as laser levels or total stations to ensure that the concrete is laid to the correct slope. This involves measuring and adjusting the elevation at various points to achieve a consistent slope across the paved surface.

- Precision and Accuracy: Achieving the correct slope is critical for the functionality and longevity of the pavement. Even minor deviations from the specified slope can impact drainage efficiency and the overall performance of the paved area.

- Types of Slopes: Slopes in concrete paving can be uniform (consistent gradient across the surface) or variable (adjusted to accommodate different drainage requirements in specific areas.

How To Calculate The Distance Between Two Level

We will discuss how to calculate the slope between two levels with the help of some given data and some basic level information like reading of level.

-

How To Calculate The Anchor Bolt For The Octagonal Foundation

-

Land Surveying And Essence of Topographical Survey

-

How To Calculate The Volume of Concrete For Octagonal Foundation

-

Distance Between Two-Level Formula

Distance Formula = 1st Level – 2nd Level/slope (in meters)

Slope Between Two-Level Formula

Slope Formula = 1st Level – 2nd Level / Distance

Given Data

slope = 2%

1st level = 1150

2nd level = 1140

Solution

First, we calculate the per-meter slope

Slope = slope %/ 100 = 2/100 = 0.02 per-meter

Distance = 1st Level – 2nd Level/slope (in meters)

Distance = 1150 – 1140 /0.02

Distance = 500 m

Verify whether the Distance is correct or not and Check per meter slope in %

Slope Formula = 1st Level – 2nd Level / Distance

Slope = 1150 – 1140 / 500 = 0.02 m slope in per meter

slope in percentage = 0.02 x 100 =2 %