Pre Stress Double Tee Design Calculation

Pre Stress Double Tee Design Calculation

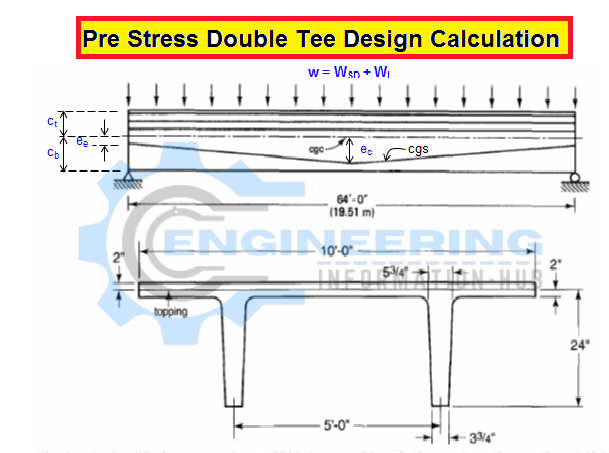

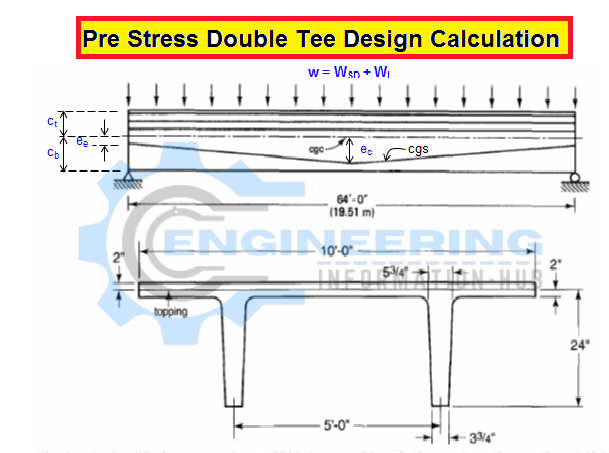

Today I have a topic about double Tee design calculation |Pre Stress Double Tee Design Calculation.

A pre-tensioned merely supported 10LGT24 double T-beam while not topping, it’s subjected to an identical superimposed gravity dead-load intensity Wsp and burden W₁.

W=420lb/ft w=Wsd+Wι

fρ¡=189000 psi fρ¡≈0.70fpu

fρe=150000psi

Determine the intense fiber stresses at the midspan because of two

1.1- The initial full prestress and no external gravity load

1.2- the ultimate service load conditions once prestress losses have taken place

Allowable stress

fc = 6000 psi concrete cylindrical strength

fo=270000 psi

fpy= 220000 psi

fpe= 150000 psi

ft = 12√f’c foot = 930 psi most allowable lastingness at the time of initial stress in conc.

fci = 4800 psi conc. compressive strength at the time of initial prestress

fci= 2880 psi fci= zero.6f’ci most allowable stress in concrete at initial prestress

fc = 2700 psi fc=0.45f’c most allowable compressive stress in concrete at service.

n = ten nos 7- wire strand tendons with a 108-Di strand pattern area unit wont to prestress beam

d=12.70 millimetre military intelligence of tendons

d = 0.50 in

Section Properties

L=64 ft

Ay = 1623.7 sq.inch y = two.00 neutral axis

A=689sq.inch At=240 tension space

Ac =449sq.inch ec=14.77 inch

lc=22469 inch4 ee=7.77inch

r²=5004sq.inch = lc/ac Sb=126inch³

Cb=17.77inch St=3607inch³

Ct=6.23inch Wd=359lb/ft

122489 inf

Initial Conditions at Prestressing

A = 1.53 sq.inch

Pi=289170 pound

Pe = 229500 pound

Maximum moment at mid-span

Md= 2205696 inch-lb

M= wl²/8

ft = Pi/Ac(1+ec/r²)+Md/Sb foot= Pi/Ac(1+ec/r²)-Mt/St

f’=-70psi

Fb=Pi/Ac(1+ec/r²)+Md/Sb fb= Pi/Ac(1+ec/r²)-Mt/Sb

fb= -2277 psi

fb 2277 psi < 2880psi allowed.

2. Final condition at Service Load, Basic methodology.

Midspan moment because of superimposed dead and loading has

M= 2580480 inch-lb Msd+Ml=Wl²/8

Mt= 4786176 inch-lb

f’ = -898 psi ft=pe/Ac(1-ec/r²)-Mr/St

f’=-898psi < fc=0.45f’c 2700psi

fb= 594psi T fb=-pe/Ac(1+ecb/r²)+Mt/Sb

fb=594psi < ft=12√f’c 930psi

3. Final service load condition by the line-of-thrust, C-Line methodology.

Since

Pe =229500 pound

Mt= 4786176 inch-lb

a = 20.85 inch a=Pe/Mt

e’=6.08inch e’=a-ec

f’=-898psi ft= pe/Ac(1-e’ct/r²)

fb=592 T fb=-pe/Ac(1-e’ct/r²)

4. Final service load condition when losses victimization the Load-Balancing methodology

At middle spen

Pt= Pe= 229500 pound

a=ec= 14.77 inch

For balance load

W₂ = 552 lb/ft

Thus, if the whole gravity load would are 552 lb/ft solely the axial load P’/A would act as if the beam had a parabolically drooped sinew with no eccentricity at the supports. this can be a result of the gravity load being balanced by the sinew at the mid-span. therefore

Total load w/c beam = 779 lb/ft Wd + (WED + WL)

Unbalanced load, Wub = 227 lb/ft

unbalanced moment Mub= 1394688 inch-lb.

f= -898 psi C ft=Pt/Ac-Mub/St

fb = 592 psi T fb= PtAc+Mub/Sb

fb=592 psi < 930 psi enable

Learn More

Bar Bending Schedule For Pipe Sleeper

Difference B/w Flexible and Rigid Pavements

Thanks for Reading Article Get more Information and share it with others.

JOIN US & LIKE MY OFFICIAL FACEBOOK PAGE